Goal:

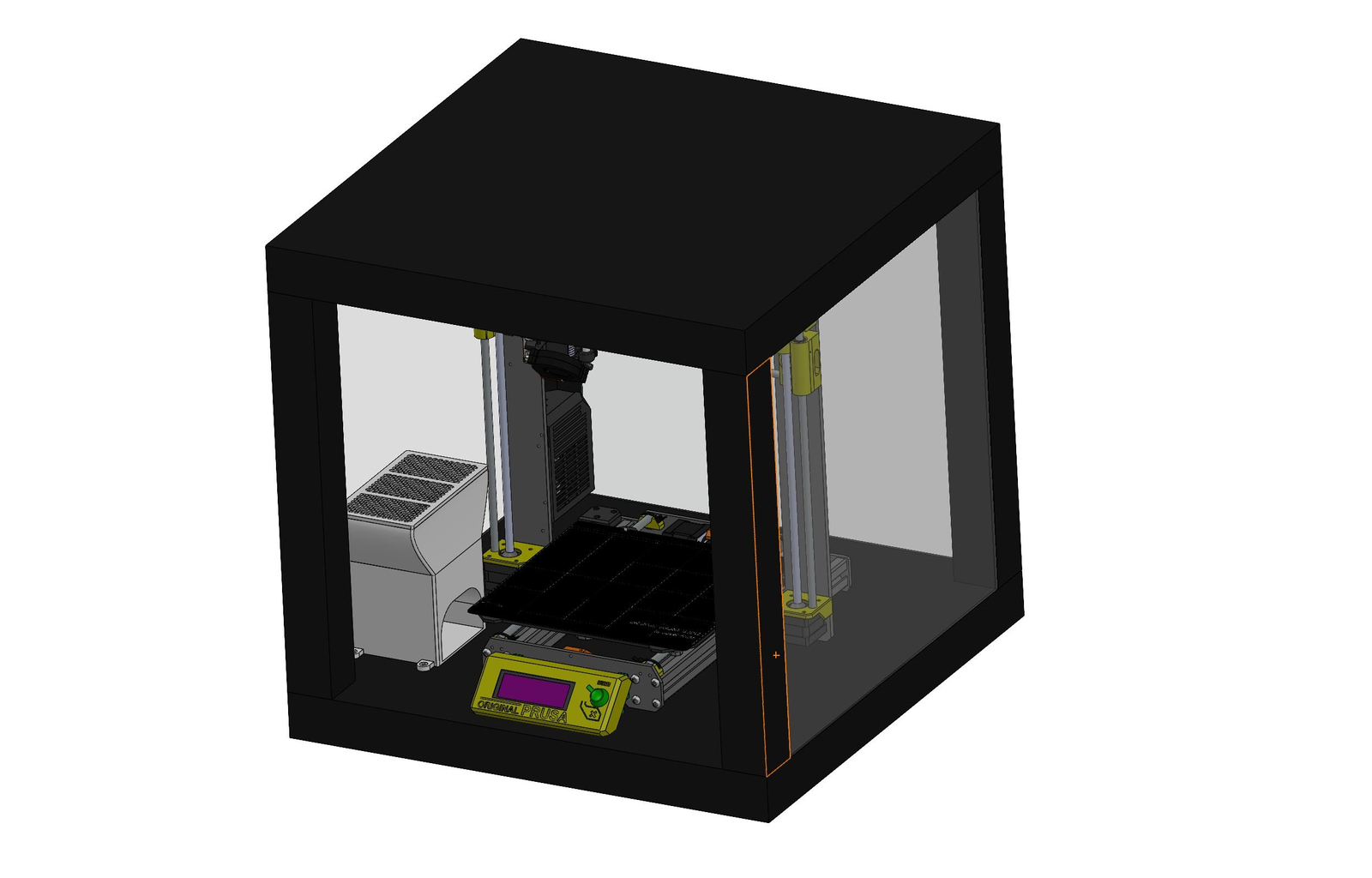

Create a compact, aesthetic air filtration unit for 3D printers to remove hazardous particles from materials like ABS, PC, Nylon, etc.

Requirements:

- Fits inside 3D printer enclosure.

- Achieves 9.45 air changes per hour (NIST standard).

- HEPA and carbon filter to capture particles as small as 0.3 microns.

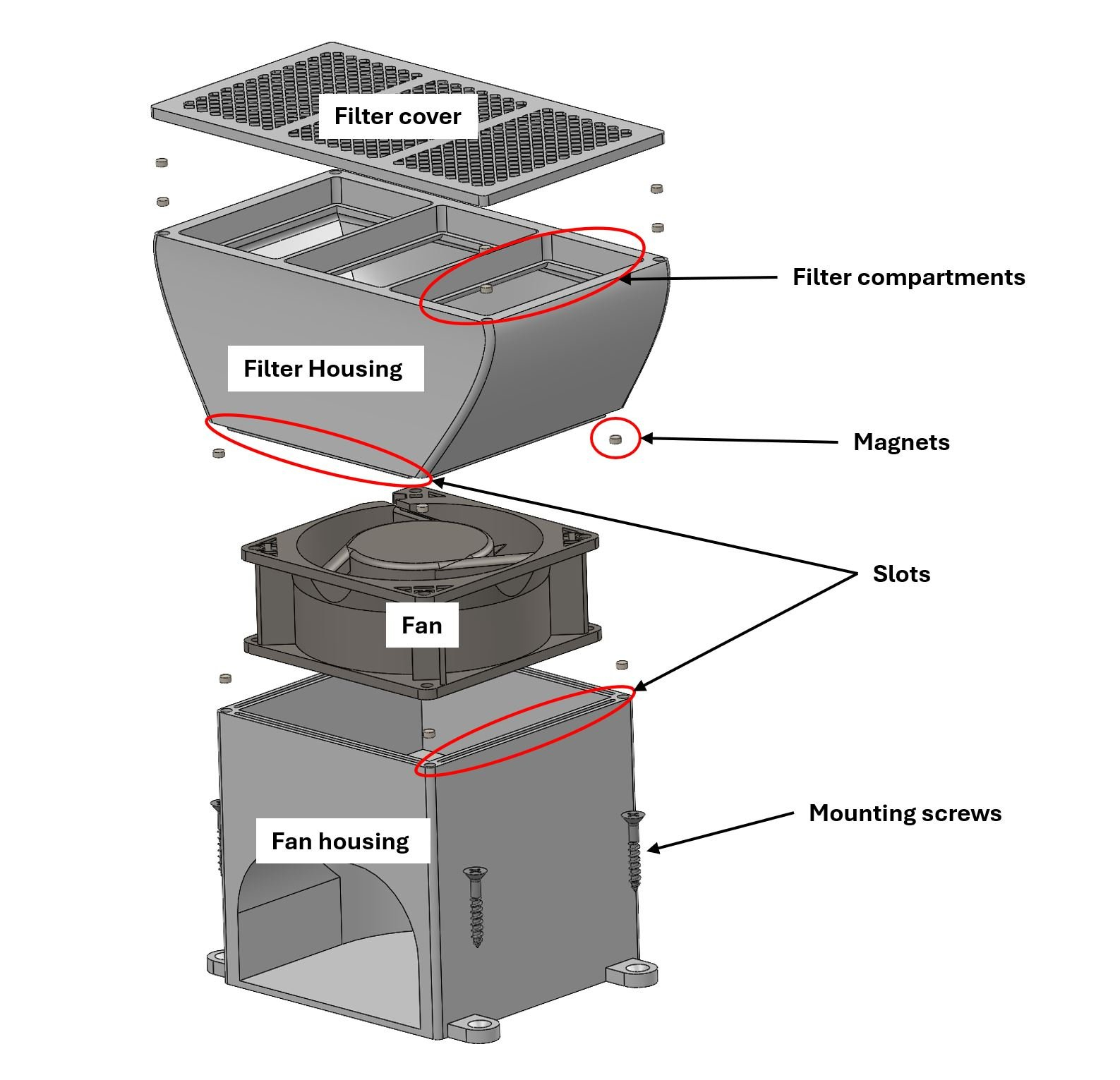

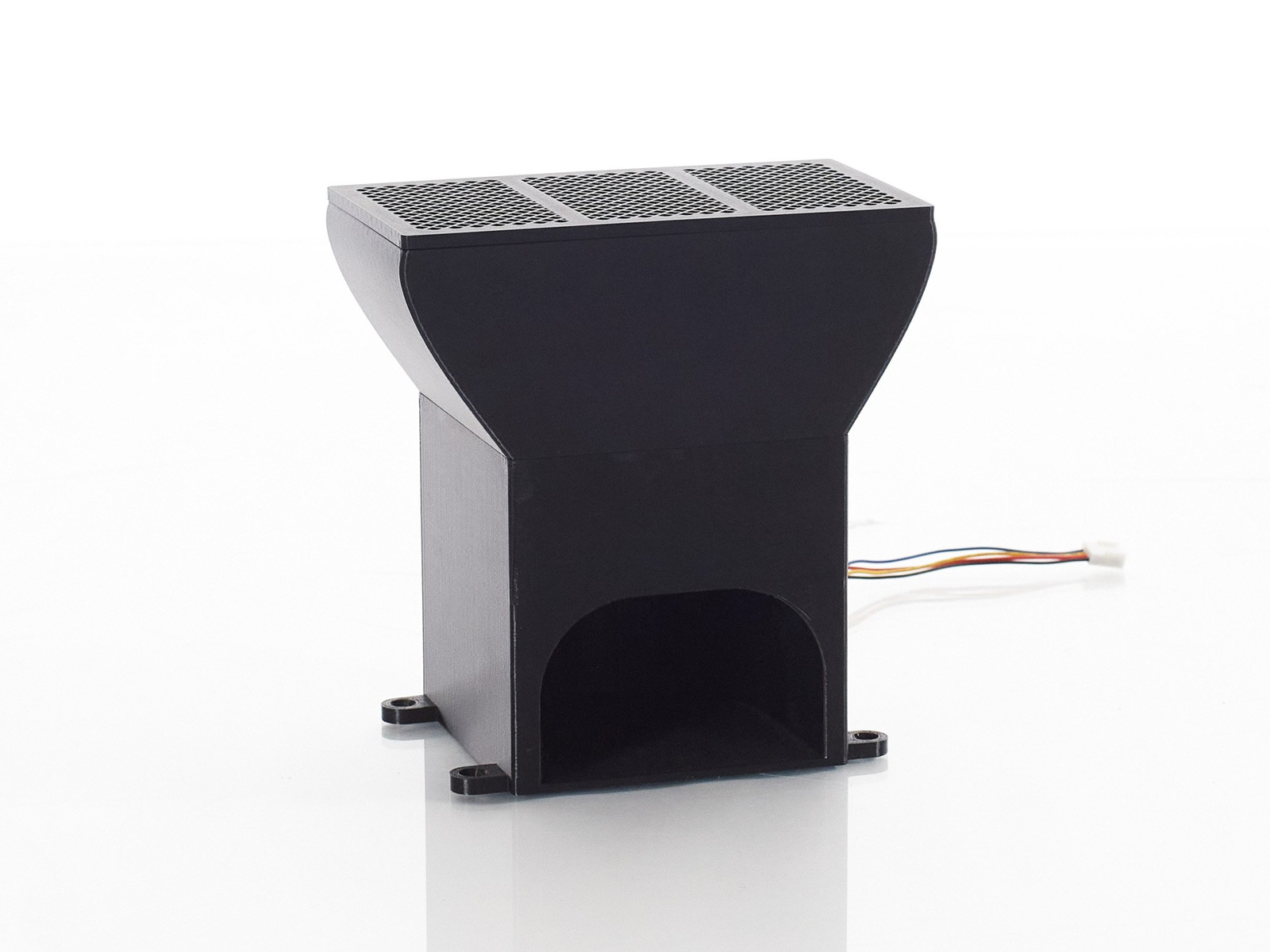

- Modular, easy to disassemble design for filter and fan maintenance.

Design Highlights:

- Optimized intake positioning and utilized a three-stage filtration system (preliminary, HEPA, Carbon).

- High static pressure fan ensures sufficient airflow.

- Configurable for three or two filter setups, adaptable to different systems.

Outcome:

Successfully created a reliable and efficient air filtration unit that provides clean, particle-free air within the 3D printing enclosure, supporting safer operation and easy maintenance.