Goal:

Create a test stand to accurately measure air filter performance curves for future applications.

Requirements:

- Consistent air velocity profile with fully developed turbulent flow.

- Airtight system with multi-point air velocity and pressure measurements.

- High static pressure blower fan for enhanced versatility.

Design Highlights:

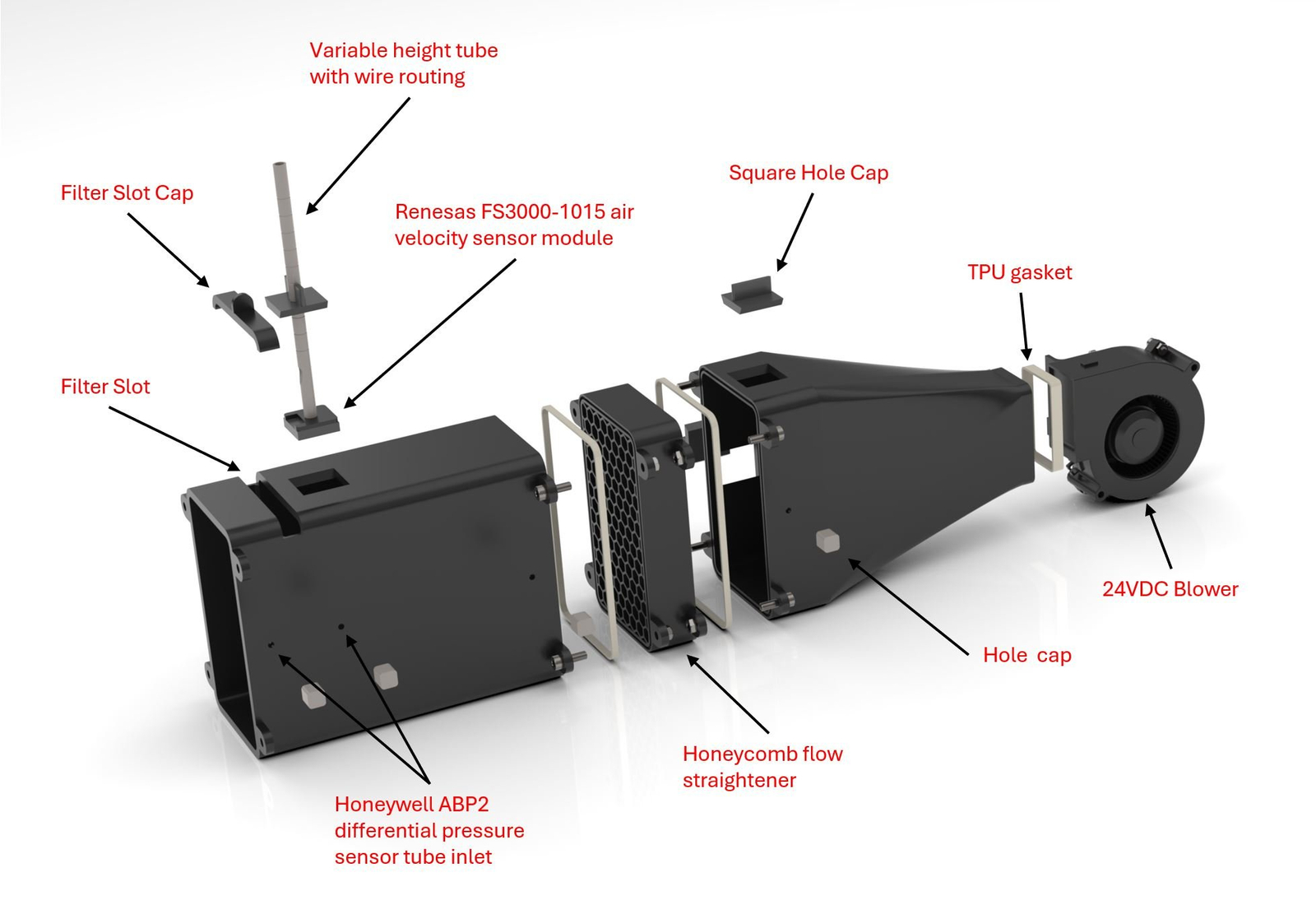

- Implementing a honeycomb flow straightener to ensure smoother, more uniform airflow.

- Modular design for flexible testing configurations.

- Honeywell ABP2 differential pressure drop measurement, and Renesas FS3000-015 sensor for air velocity before and after flow straightener.

Outcome:

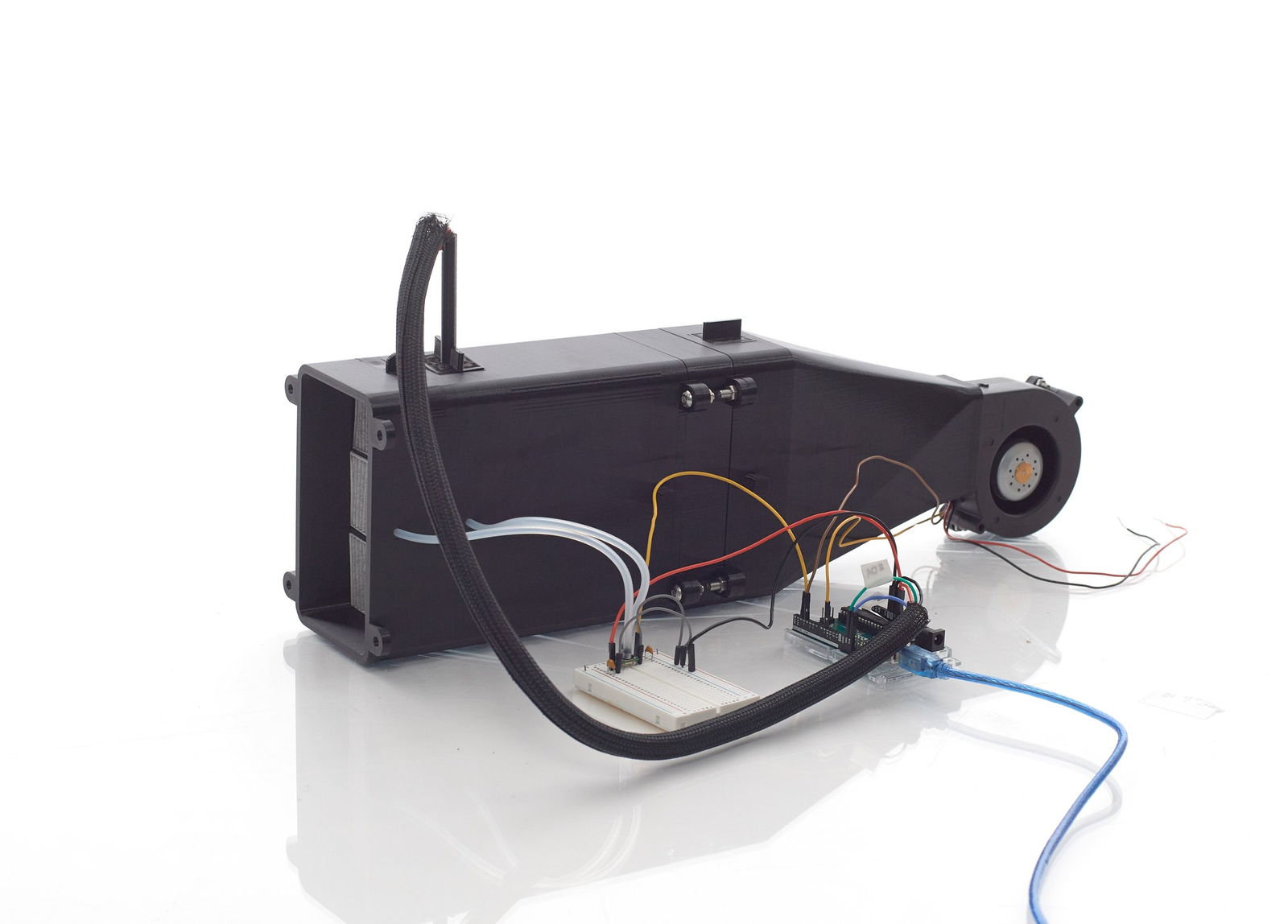

Designed and built a test stand to evaluate filter performance, focusing on measuring air velocity and pressure differentials. While still a work in progress, the current design has highlighted opportunities for improving airflow uniformity. The fan's downward bias creates non-uniform flow, prompting further investigation into solutions such as extending the tunnel length, incorporating diverging and converging sections, and repositioning the fan to the suction side for better flow consistency.

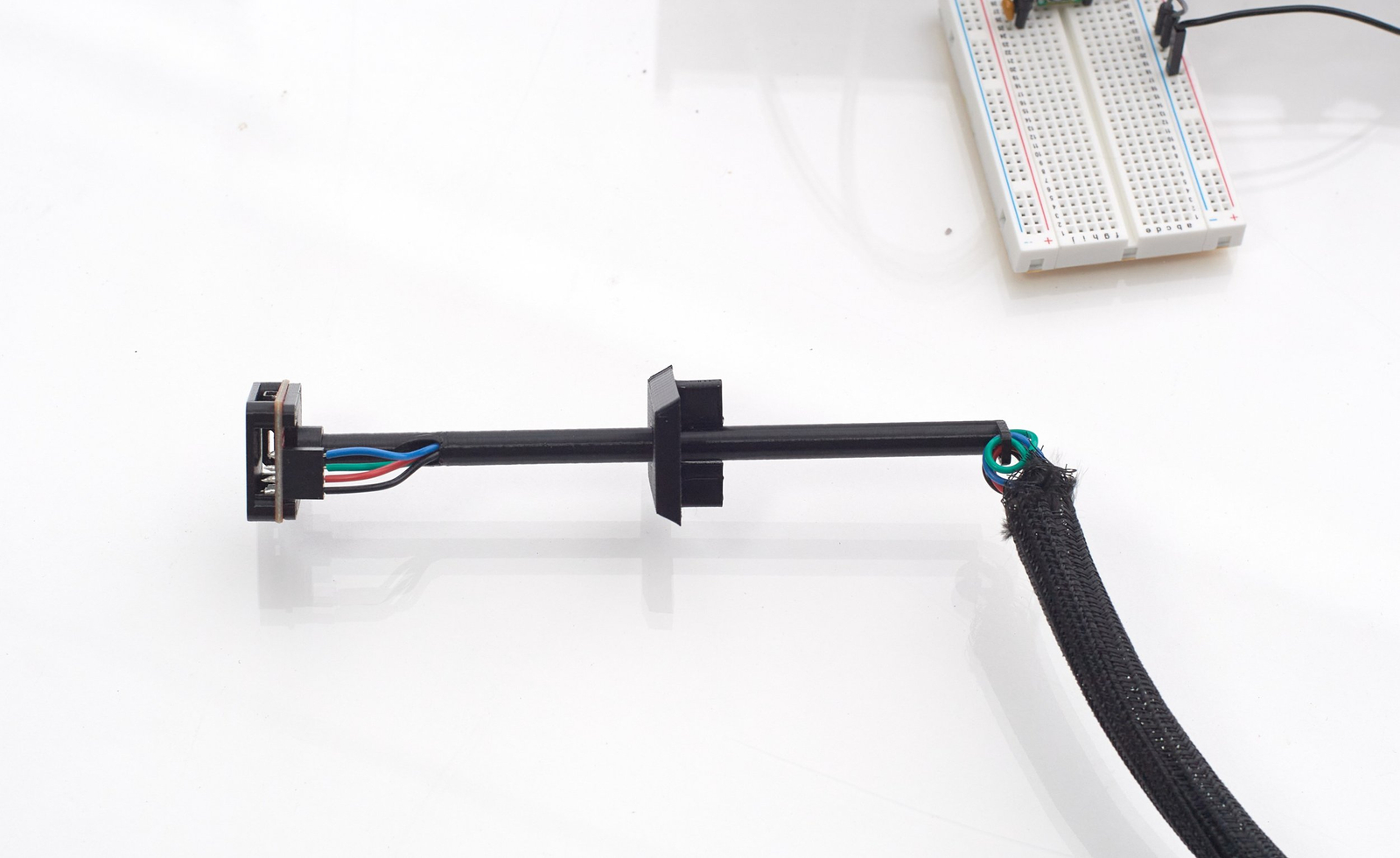

Renesas FS3000 Air Velocity Sensor

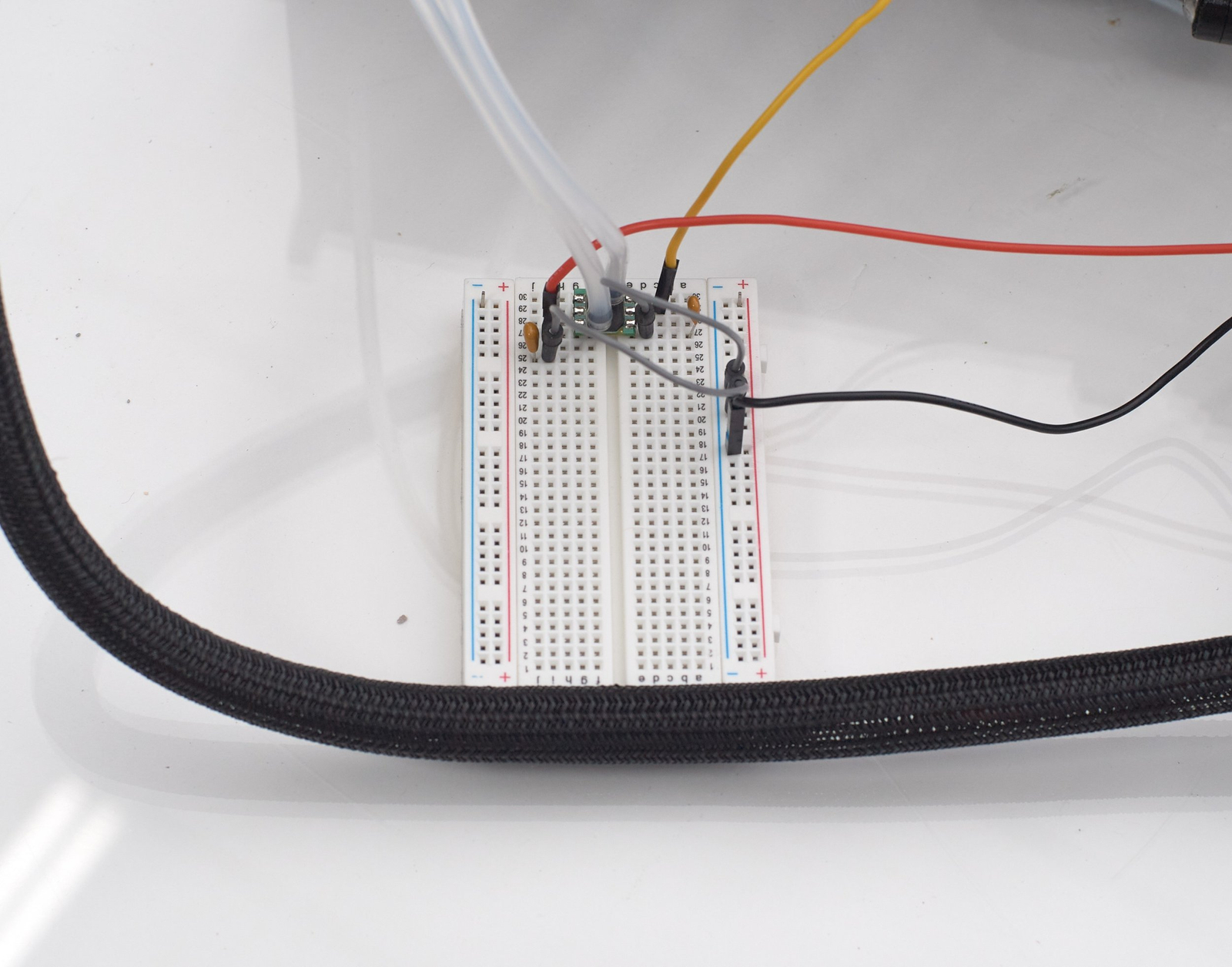

Honeywell ABP2 Differential Pressure Sensor Circuit