Goal:

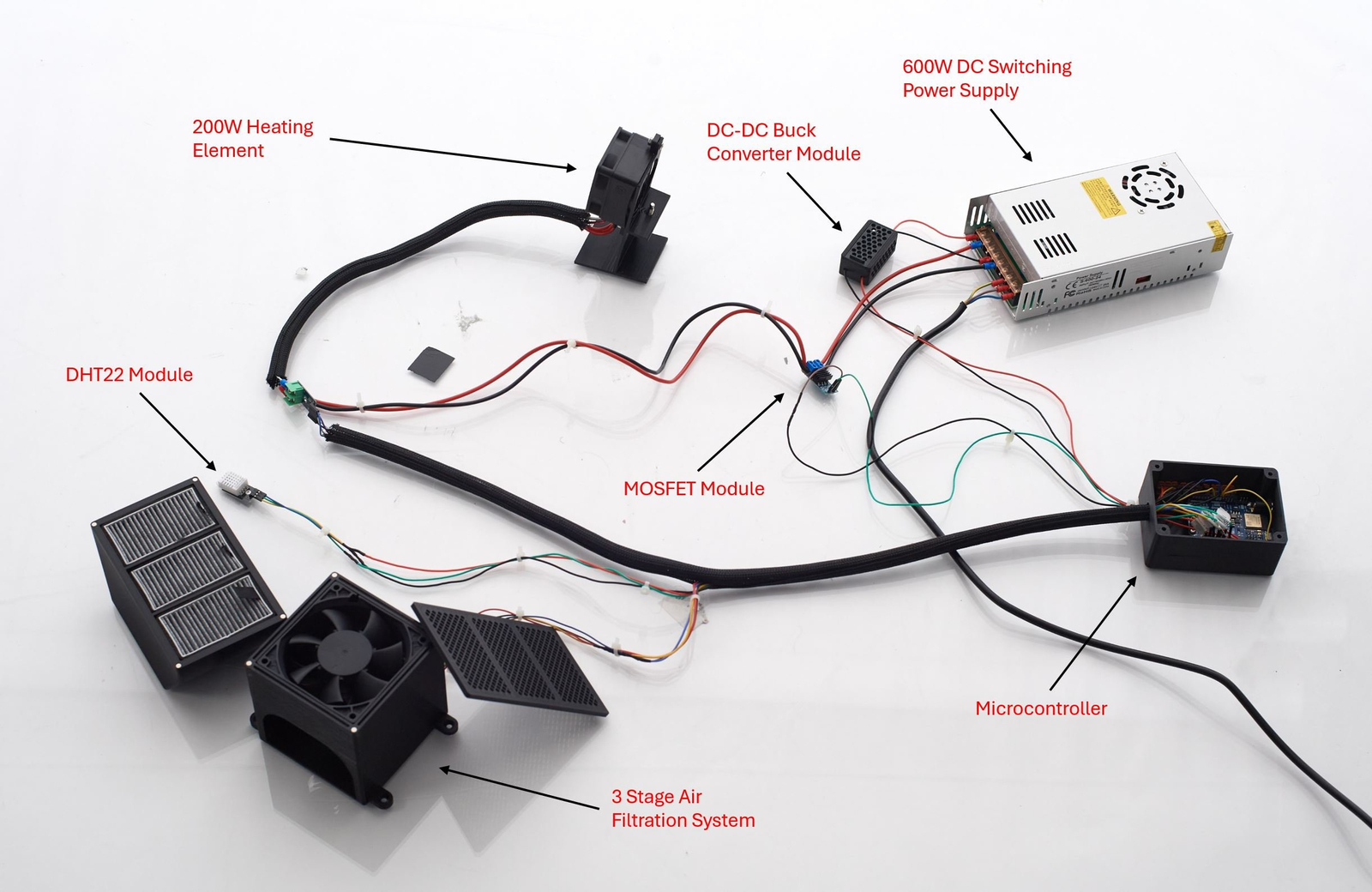

Integrate essential 3D printing components – auto heater, air filtration system and sensors – into a unified assembly for enhanced system control and functionality.

Requirements:

- Environmental monitoring and IoT control.

- Power management for both fan and heating element.

- Single AC-DC power supply and microcontroller for system logic.

Design Highlights:

- Enhanced MOSFET with heat sink and DHT22 sensor (future quality sensor).

- Currently utilizing Arduino but switching to Raspberry pi for AWS integration, USB hosting capabilities and custom frontend.

- DC-DC converter to power fan and controller.

Outcome:

Successfully created a cohesive 3D printing environment with IoT capabilities, improving control over printing conditions and ensuring compatibility with advanced materials through effective heating and filtration management.