Goal:

Evaluate the dimensional accuracy and capability of my 3D printer.

Requirements:

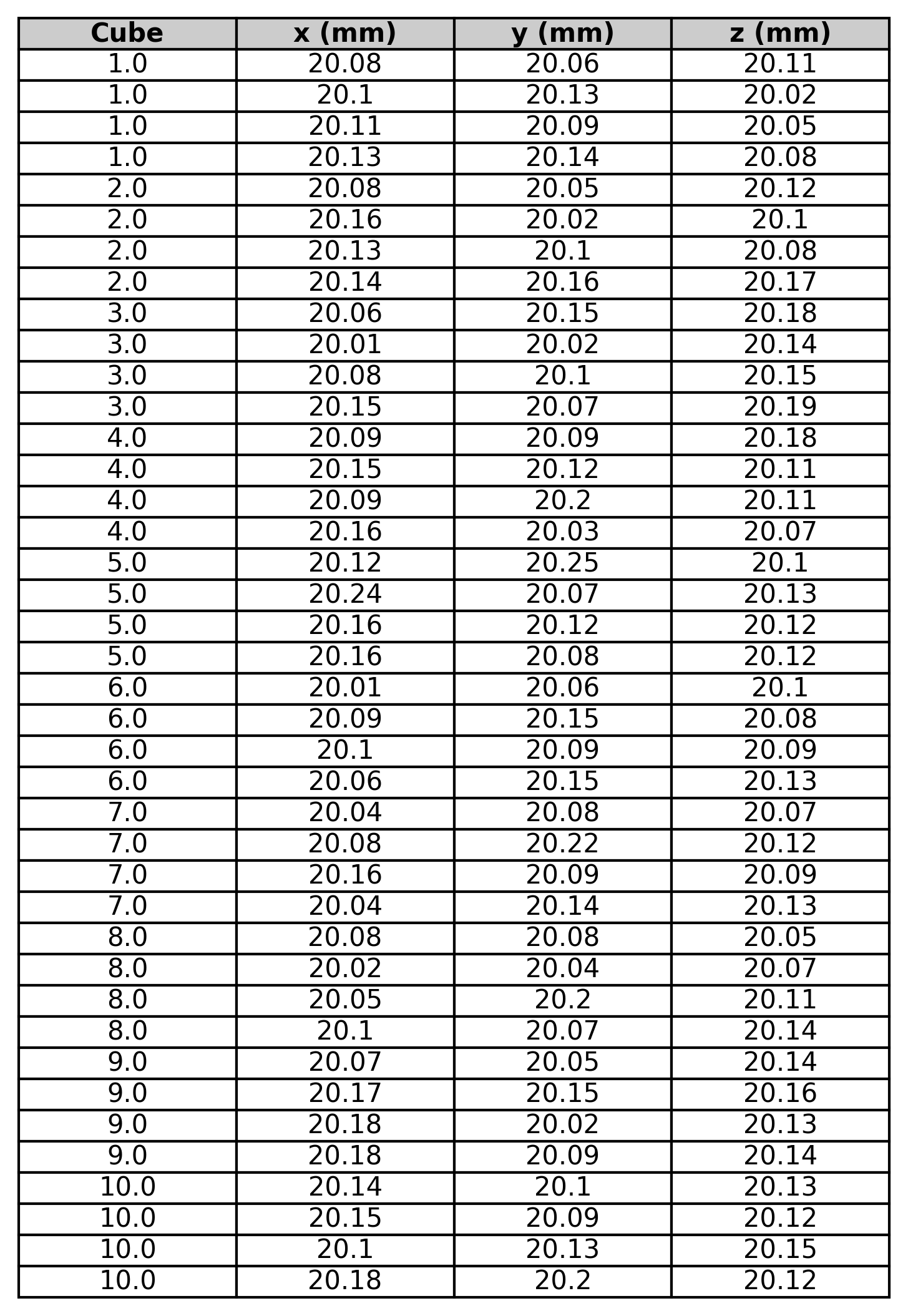

- Collect 40 samples for X, Y, and Z dimensions on a calibration cubes.

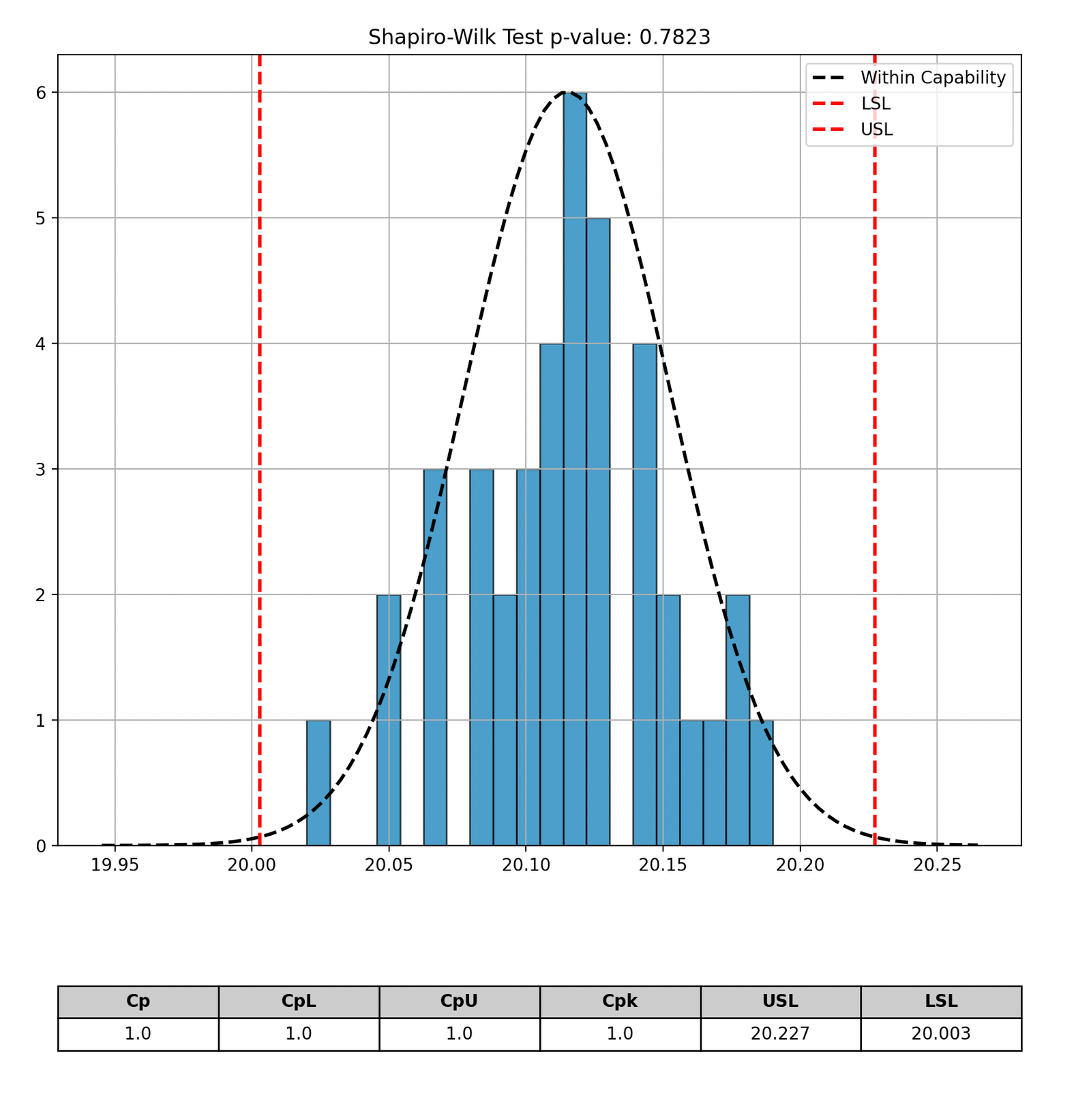

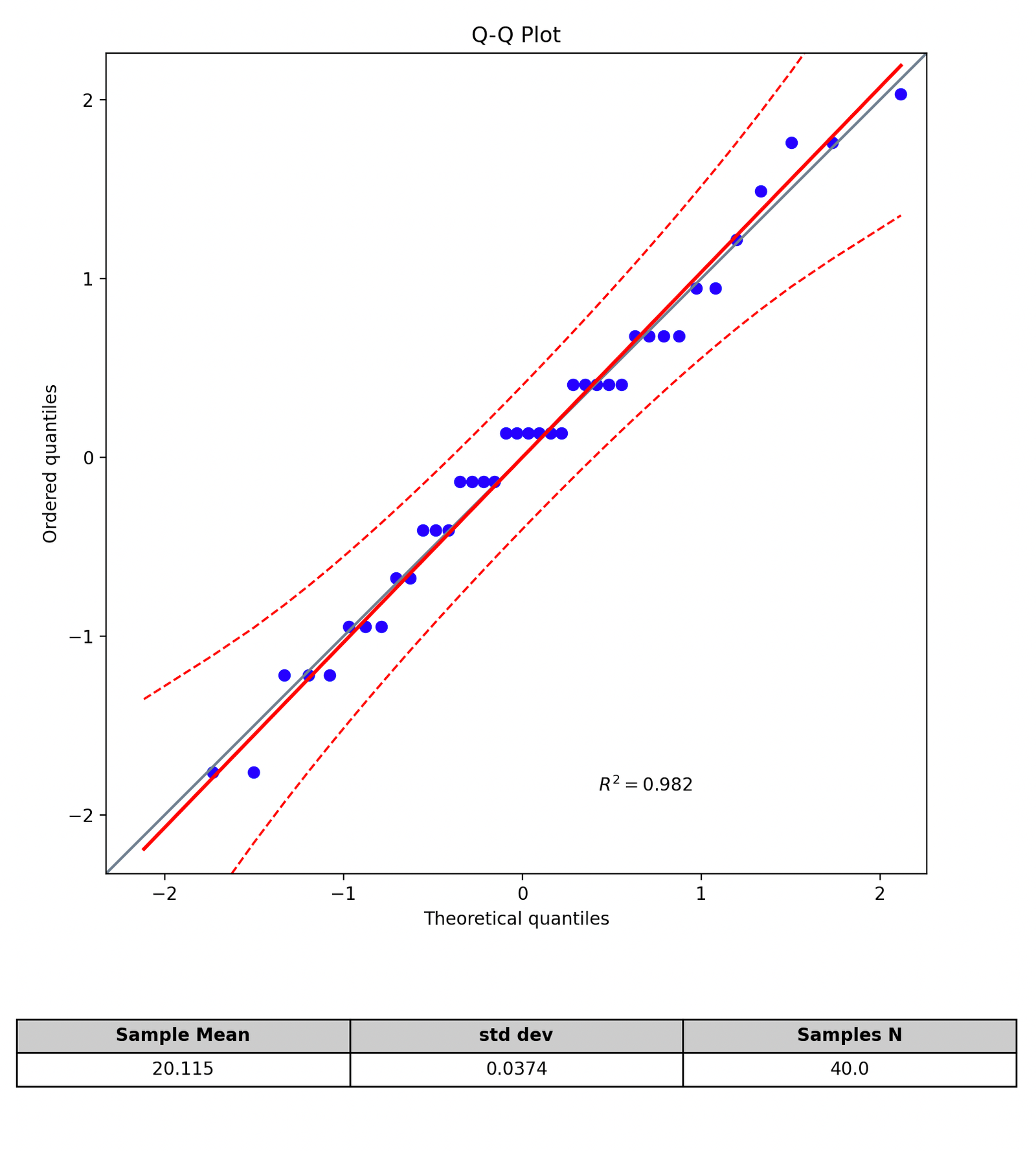

- Verify that the data follows a normal distribution.

- Use statistical analysis to determine the printer's process capability.

- Establish a baseline for monitoring drift over time.

Analysis Highlights:

- Measured height from a flat surface for consistency.

- Confirmed normal distribution using the Shapiro-Wilk test and QQ plot.

- Defined lower and upper specification limits (LSL, USL) as ±3 standard deviations, ensuring that 99.73% of measurements fall within the range, aligning with standard statistical process control practices.

- Calculated Cp, CpL, CpU, and Cpk values to assess process capability.

Outcome:

Successfully established a baseline capability assessment for the 3D printer. This allows for tracking dimensional drift over time, improving maintenance and recalibration scheduling to ensure consistent print accuracy.